Calculating product's pricing is always a challenging problem for every company. Without ERP system, it's very hard to have a good analysis of your production, because the manufacturing is combined with different processes with many types of materials to be consumed. You can purchase materials from several vendors with different pricings. Besides, each work station has its own cost of machines and cost of labors. Let's see how the system help you calculate product pricing.

How product pricing helps you

If you know exactly your product pricing, you can choose an appropriate price to obtain your margin while selling goods and services.

With the help of product's cost, you can easily change your price unit to have best margin.

Bill of materials

Firstly, you have to define exactly bill of materials for each product.

A good bill of materials should contain materials, time and operations to produce that product.

Basically, with materials, you can set up type of material, corresponded quantity. With operations, you need to clarify each steps, working station, description for workers, planned time for manufacturing, work center capacity, time efficiency, cost by hour, cost by labor, time for setting-up, time for cleaning, targeted OEE...

For each product, you can set a fixed cost or it can be automatically filled in after every purchase order.

If in one manufacturing order, you use one type of material but from different lots/series, the pricing of each lot you consume will be calculated in the manufacturing order.

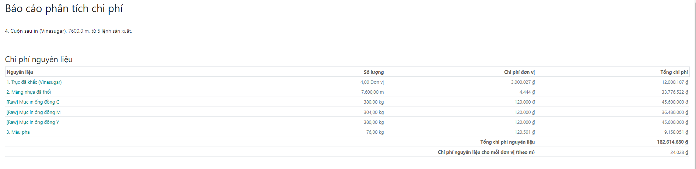

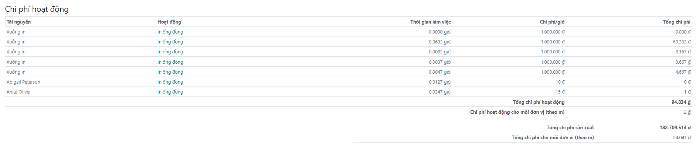

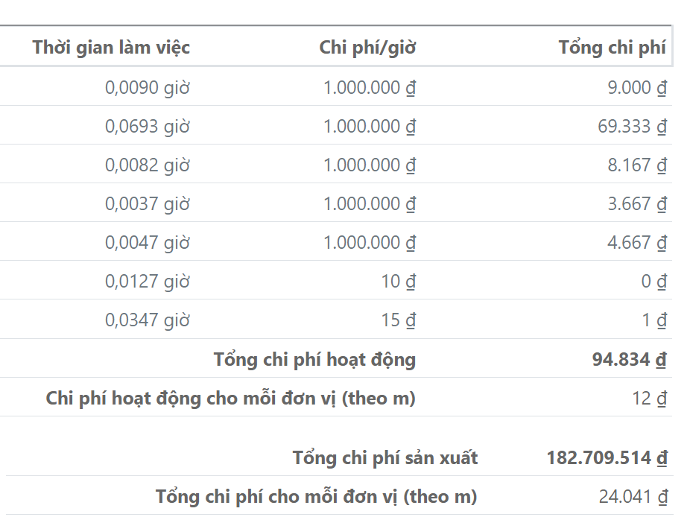

Finally, after completing manufacturing orders, you can have a cost analysis for your products based on real production time and consumed materials:

Explore how amazing an ERP system can help your business

Join us and make your company a better place.